Dependence on crude kerosene-fuelled heating stoves and hundreds of loud generators due to epileptic power supply have created an uneasy way of doing business for about 3,000 micro and small-scale manufacturers at the Ariaria International Market Aba in Abia State, Daily Trust on Sunday reports.

This is in spite of the federal government’s push for ease-of-doing-business nationwide, with a target of making Nigeria a destination point for investors.

Although about 2,000 megawatts (MW) are said to be injected in the national power grid daily, businesses and industrial areas continue to suffer blackouts with some spending 40 per cent of production cost on fuel generators, said a report by the Manufacturers Association of Nigeria (MAN) this year.

According to Daily Trust on Sunday investigation at the ever-busy market, the power supply situation has continued to be a perennial problem in the industrial section, even after the intervention of the Rural Electrification Agency (REA) – AMES Power, providing lighting for the mainly retail section of the market complex, said to have about 4,000 shops at Ariaria 2.

The Ariaria International Market was established in 1976 and is prominent for Micro, Small and Medium scale Enterprises (MSMEs) manufacturing various categories of consumer goods including bags, footwear, clothing (individual, industrial and military) and exporting goods across Nigeria and some African countries.

This economy stimulating market is under the franchise of the Enugu Electricity Distribution Company (EEDC). The Enugu DisCo is the only power firm that supplies electricity to vast consumers in the five eastern states with an estimated 732,000 customer base in the five states. The DisCo, despite its vast coverage area, gets just nine per cent of whatever the national grid generates daily. For instance, out of 4,900MW peak energy on the afternoon of September 1 (12:05), Enugu DisCo had 445MW, according to real-time energy data from the System Operator (SO).

Benin DisCo also with nine per cent allocation and about 800,000 customers got 420MW to distribute across Edo, Delta, Ondo and Osun states. But Eko DisCo which covers a part of Lagos and Ogun, with around 500,000 customers got 614MW (about 12 per cent, highest among the 11 DisCos) during the same period.

Due to the size of Ariaria market and its environs, EEDC, it was observed, has two service centres for the area comprising Ariaria I Service Centre at Faulks Road and the Ariaria II Service Centre at the Aba–Owerri Road, all in Aba town.

Manufacturers short-changed?

There are concerns about whether the manufacturers who are customers of EEDC in Ariaria market are short-changed as they said they have never received the power supply quantum that they demand.

According to tariff records of EEDC under its Service Reflective Tariff (SRT) band, the Ariaria market and industrial area is pegged at only eight hour of power supply daily on Band D with 11 kilovolts (kV) lines despite being a heavy consuming area. However, power supply within the market does not go beyond three to four hours, according to shoe, bags and textile manufacturers in the market.

This is despite demand by the manufacturers for at least 10 hours of power daily, from 8am when the market opens to 6pm when it closes. Although most of the manufacturers said they could work overnight if there is constant electricity.

Based on the EEDC records, even if the Distribution Company (DisCo) provides power supply based on the eight hour it agrees to supply, the market which operates for 12 hours daily, will still be on four-hour black out daily, despite being charged average of N34 per kilowatts hour (kwh) of electricity.

With EEDC standards, Ariaria market community without power for up to four hours daily could suffer 120 hours cumulative blackout every month (equivalent to five days) while paying for darkness.

Manufacturers, workers confirm production drop over outages

Daily Trust on Sunday spoke with over 50 shoe and bag manufacturers, and workers in the market who narrated their experiences about power supply. They called on the federal government to specially intervene in solving the perennial power outages in the market with over 3,000 active production outlets from about 37,000 shops in the market, engaging in textile, tailoring, leather works, footwear production, printing, tools and machinery fabrication as well as pharmaceuticals.

At the Powerline Shoe Plaza in Ariaria International Market, 20 of the manufacturers decried the poor power supply from EEDC in the market section.

Hon. Goodluck Nmeri Joseph, 62, produces shoes and has spent 32 years in the market. “I have four apprentices and six employees working for me. Our shoes are taken to as far as Gabon, Cameroon, Niger, and Ghana. This is a potentially ‘better time’ for us in the shoe making business because the influx of China shoes has reduced and artisans can make huge profits.”

However, he complained about electricity saying, “We generate power from generators and we use kerosene powered (heating) stoves (to work on leather). A litre of kerosene now is N320 and we consume up to four litres daily because we use the stove to kindle the strength of adhesive that’s applied on the shoes.

“We open from 7am to 6pm and I buy about six litres of petrol daily for the generator. Because of this, we are limited to producing just hundreds of shoes manually every day but with our heavy-duty machine, we can produce in thousands,” said Nmeri.

Along with generator maintenance, Nmeri said he spends over N7,000 per month on his generator that runs for two to three hours daily. He spends another N8,000 paying monthly electricity bill to EEDC for a less than five hour daily supply.

Chikodi Onyebudi, a shoe–making apprentice, has spent four years in the market, witnessing the unfortunate blackouts and the heat from the stoves.

“The electricity situation is not good enough for us, we had power yesterday for just two hours, how long the generator lasts depending on the amount of fuel we buy, and we do day and night shifts.

“Once there is power, I can produce more than 100 pairs as an apprentice; you can see heat all over me as I use the stove to work and I use the power bank to connect a bulb to provide light.

“I pay N200 daily to charge the power banks, which is cheaper than running a generator,” he noted.

Like Chikodi, another apprentice, John Nwogu, said constant power supply would be an incentive.

“The business is no longer booming because of the power challenge. The younger boys are now into Okada riding since they cannot stand this challenge; they have resorted to ‘sharp-sharp’ business,” said Nwogu.

Another shoe manufacturer, Mr. Benedict Enyinnaya, said he pays around N10,000 estimated bill monthly with four-hour average electricity daily. With constant supply, he could produce 100 pairs of shoes daily but now does only 30 a day manually.

“The power plant (AMES Power) commissioned by the vice president doesn’t get to the Power Line which is the industrial cluster but is mostly used by retail shop owners. Government doesn’t know whether we exist or not,” he noted.

Ifeanyi Okereke, another shoemaker, shares a generator with his neighbour due to the poor power supply, he said.

“I contribute to the purchase of fuel in my neighbour’s generator because mine is bad. I support with N1,000 to N1,500 a day, sometimes and I produce 150 shoes daily but with steady power I have all the machines to produce 350 pieces of shoes daily.”

Generator ‘Mini-grids’ thrive at Bakassi section

The Bakassi market section is where bags and belts are produced. One of the 15 manufacturers who spoke to Daily Trust on Sunday, Elder Ukagha Sunday, has been in the market for 32 years with two manufacturing outlets and four employees. The bag maker, who also exports products, said there is special arrangement in this area. Due to poor supply from EEDC, they teamed up to provide a Lister Peters generator as a dedicated mini grid.

“Each shop pays N200 daily and N1,200 per week. I don’t use a generator, the cost of fuel and maintenance of the generator is high; all the profits goes into fuel and purchase and generator maintenance.”

Kingsley Madu is one of those who own the Lister generator ‘mini-grid’ in the market. Madu, who also produces bags, said, “As there is no power, I use my Lister to supply power to others; there are several people doing Lister generator business in the market. I am not happy with the epileptic power supply but it’s a good fortune for me because every manufacturing outlet connected to the generator must pay me N200 daily. Sometimes, I use N20,000 to service it every two weeks and I have 50 customers on it.”

However, Kelechi Okoro, who has two workers and seven apprentices, said the problem with the Lister generator is that when the owner travels to buy raw materials, the users will have to wait.

“We spend almost N5,000 monthly on the generator bill as it works between 8am and 6pm daily. The Osinbajo light (AMES power) is working within Ariaria 2 but it has not reached the Bakassi section which is the industrial area.”

Okoli George, another manufacturer added that the Lister power comes from 8am to 1pm, then a one-hour break and resumes from 2pm to 6pm when the market closes.

“We at the Bakassi market (an industrial sector) of the Ariaria market are yet to access the national grid; I am thinking of relocating my industrial machine to my house because of no power,” said Okoli. One of the apprentices, Promise Achara, said the lack of power supply discourages him from learning bag-making. “Even with the Lister power, there is a limit to what you can do. So, the national grid is better and that is what we don’t have.

“I help my boss produce more bags, I should have gotten the opportunity to learn all these machines but I can’t learn, I can’t wait for power to learn because I am getting older daily, I manage to produce 50 a day when I’m supposed to be producing 200 with grid energy.”

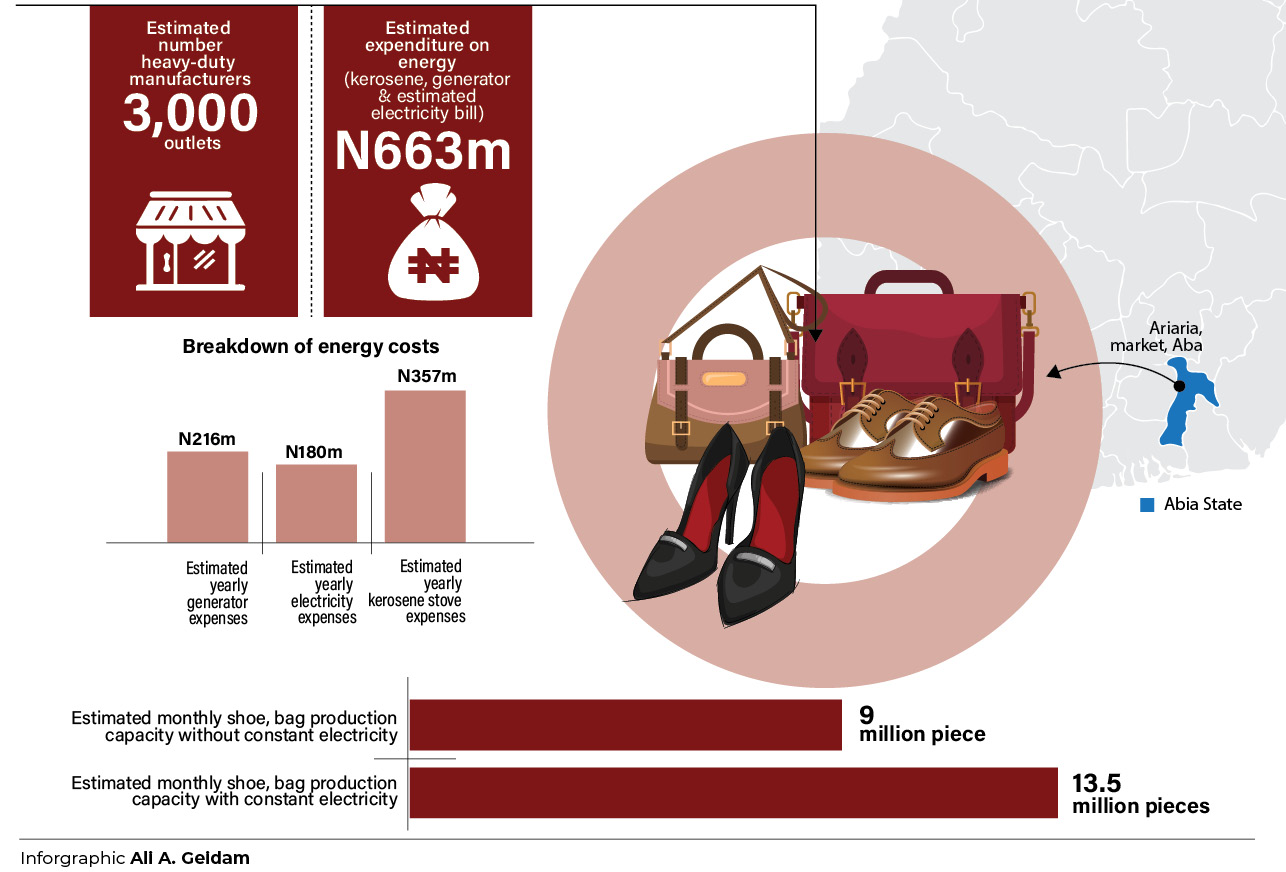

Producers spend about N931m on generators, kerosene, estimated bills yearly

This paper also computed the heavy-duty manufacturers’ energy cost for the about 3,000 Micro and Small Manufacturers. At an average N6,000 spent on generators monthly, about 3,000 of the Ariaria Market manufacturers would be spending N18 million monthly on generators or N216m a year.

At an additional average of N5,000 spent on estimated bills every month for each manufacturer on his outlet, this would add another N15m monthly on grid electricity bills, or N180m a year.

At a combined cost of N33m monthly on generator and grid energy expenses, they are spending at least N396m annually.

The manufacturers also spend on kerosene for their kerosene-fuelled heating stoves for the shoe and bag making process. Spending on kerosene is about N620 daily for two litres. This means an outlet can spend N3,720 for six days every week and N14,880 monthly. It means for the majority of the 3,000 manufacturers that use kerosene-fuelled heating stoves, they could be spending N44.640m every month and N535.6m every year on kerosene.

On the total energy cost, the estimated 3,000 manufacturing outlets in Ariaria market are said to be spending N931m annually on energy, comprising N396m on generator and estimated bills, and another N535.6m on kerosene annually.

Gas-power ‘lights up’ other retail shops

At the retail section of Ariaria market where it is mostly about the sale of items, the AMES gas-plant serves the shop owners. Some of the 15 shop owners interviewed expressed satisfaction with the supply. However, some others emphasised that the supply is not for heavy duty tasks or production.

Tochukwu Uzogbuo who owns a hair accessory shop in the section said it is just for lighting, charging of phones and fans. “The power supply runs from morning to evening and we pay around N5,000 monthly.”

Mrs Ofonime Thomas sells fabric in the market. Her experience with the power supply is similar. “The Osinbajo power is okay for me because I don’t use it for anything big. But there are my colleagues at the Bakassi market who are really suffering from the lack of power supply,” she noted.

Union, members decry drop in production capacity

Some union members at the Ariaria market also spoke about their efforts towards having improved electricity in the market, especially at the Power Line and Bakassi sections where about 3,000 manufacturing and heavy-duty outlets operate.

“On several occasions in the past, we have addressed the press on the electricity challenges, we met with delegates from Abuja after the construction of the Ariaria Market Energy Solutions Limited (AMES) by REA, and attended workshops and seminars with the state government and kept appealing to them without response,” said chairman of the Power Line Traders Association, Goodluck Nmeri.

“We protested through the media, letters to the authorities that the AMES is currently used by non-industrialists like provision shops, while the core manufacturers/industrial clusters don’t have access to power,” Nmeri added.

Another union member at the Bakassi Market, Kelechi Onukuri, said the heavy-duty manufacturers outlets were not connected to the AMES gas-powered plant in the complex but rely on the power from EEDC which he said is poor.

“As you can see, we don’t have power, it comes once a while. But up to six litres of fuel on the generator can last for eight hours for production. We don’t make use of the power plant commissioned by the vice president; but we get patronage (for our goods) from outside the country.”

Overall, the small-scale manufacturers said if the potential of the market is well harnessed, it has the capability to reverse the high unemployment rate Nigeria faces while also reversing the social crisis escalating in the southeast.

This is because with the current epileptic power nature, a manufacturer can only produce an average of 50 shoes or bags daily, reaching about 1,500 pieces monthly which can be exported.

However, with 10 hours of power supply, a manufacturer’s capacity could double to 100 pairs of shoes or bags daily and reach 3,000 units monthly. At this rate, the about 3,000 heavy-duty manufacturing outlets would have the capacity to export over 9m shoes, bags and textile materials every month which would be over 50 per cent higher than their current capacity with ripple effects on job creation and economy-lifting activities.

Dependence on kerosene-heating stoves harmful – Expert

Daily Trust on Sunday further investigated the implications of using kerosene heating stoves in the shoe and bag production process, which manufacturers have resorted to due to poor electricity supply from the grid.

According to a 2018 Factsheet from the World Health Organisation (WHO), 3.8m people globally die prematurely every year from illness traced to air pollution caused by the inefficient use of solid fuels and kerosene. Among these 3.8 million deaths, the data showed 27 per cent are due to pneumonia, 18 per cent died from stroke, 27 per cent from ischaemic heart disease, 20 per cent from Chronic Obstructive Pulmonary Disease (COPD) while the other 8 per cent died due to lung cancer.

Commenting further on the implications, the Director, Health of Mother Earth Foundation (HOMEF), Nnimmo Bassey, said the process of using a stove has a negative effect on the health of the workers and also releases greenhouse gases into the atmosphere.

“So, it has an effect on the people by having an effect on the quality of the air around, as well as being toxic to the people who are working there. This has a direct effect on the health of the worker and the health of the people. This depends on the type of chemical they are using for the work, but generally, you can be sure they could have breathing difficulty and other airborne diseases.”

The environmental rights activist said the process releases black carbon (soot) similar to that from big refineries, gas flaring and illegal refineries.

“But it could also come from activities of this nature, like burning rubber and plastic substances. Some of them have a hydro-carbon base and are very toxic to health. The workers would have to wear protective kits before doing this,” Bassey advised.

EEDC says manufacturers’ sections on 20hr power supply

Meanwhile, EEDC (Enugu Disco) has denied the claims by the consumers that they were getting poor power supply from the EEDC network.

The Head, Corporate Communications of EEDC, Mr Emeka Ezeh, in a response to enquiry, said the industrial area of the market, especially the shoe producing areas, are on ‘Band A’ and getting more than 20 hours of supply.

He said, “Within the areas you mentioned, we have two transformers serving the Ariaria International Market, they are, Aba North Shoes Plaza and Umuehilegbu Shoes Plaza.

“These transformers are feeding from our Aba-Owerri 33 kilovolts (kV) feeder which is on “Band A”, with more than 20 hours availability/supply. These two transformers are being managed by the market and the customers are enjoying supply.”

Mr Ezeh however noted that maybe the poor supply is at another section of the market. “It is therefore possible that the area you might be referring to is the one that is being served by the Independent Power Producers and I am not in a position to speak on that.”

He also denied any 11kV feeder in the Ariaria market. “We (EEDC) do not have any 11kV feeder line into the market.” However, this is contrary to its approved and published Service Reflective Tariff (SRT) specifying eight hours (Band E) for Ariaria market on 11kV feeder.

We’re monitoring power firms’ performance – NERC

Responding to Daily Trust on Sunday enquiries on how poor electricity supply is crippling the huge potential of the Ariaria market, NERC – which is the power sector regulator, said a section of the market is managed by a licensee other than EEDC.

“The commission in compliance with the NERC regulatory powers and licensing regulations approved the issuance of an independent electricity distribution network license to Ariaria Independent Distribution Network Company Ltd. The commission is constantly monitoring the performance of licensees and it expects the licensees to honour their obligations to their consumers,” said the General Manager, Public Affairs at NERC, Dr Usman Abba-Arabi, in an emailed response.

On the situation of supply around where EEDC superintends, which is where the over 3,000 small-scale manufacturers operate, NERC stated that each DisCo has signed off on the Service Base Tariff (SBT) and there is a monitoring tool that the Commission uses to measure their performance.

Abba-Arabi further said, “We expect the DisCos to perform based on what they signed. Where they don’t meet the minimum service level, the commission applies its relevant sanctions and it includes compensation to customers.”

This report was facilitated by the Wole Soyinka Centre for Investigative Journalism (WSCIJ) under its Regulators Monitoring Programme.

Join Daily Trust WhatsApp Community For Quick Access To News and Happenings Around You.

Join Daily Trust WhatsApp Community For Quick Access To News and Happenings Around You.