An entry at www.sciencedirect says, “Extensive tar sands with reserves of about 41 billion barrels of oil are known to occur in cretaceous terrigenous sediments in Ondo and Ogun states. The hydrocarbon occurs in two predominantly sandy zones separated by an eight-metre-thick oil shale.”

Another report says Edo and Lagos states too have tar sands deposits.

What are tar sands? “Tar sands are a combination of clay, sand, water, and bitumen, a heavy, black, asphalt-like hydrocarbon. Bitumen from tar sands can be upgraded to synthetic crude oil and refined to make asphalt, gasoline, jet fuel, and value-added chemicals.”

The names of two ministers are part of the title for this item because the ministries they supervise need each other and the ministers need to collaborate in the interest of Nigeria.

The Federal Ministry of Works and its contractors rely 100 per cent on inputs that originated from Nigerian and foreign mines to construct roads, bridges, drainage, and every road furniture. The main materials include water sand, gravel, stones, iron and steel, bitumen, or asphalt.

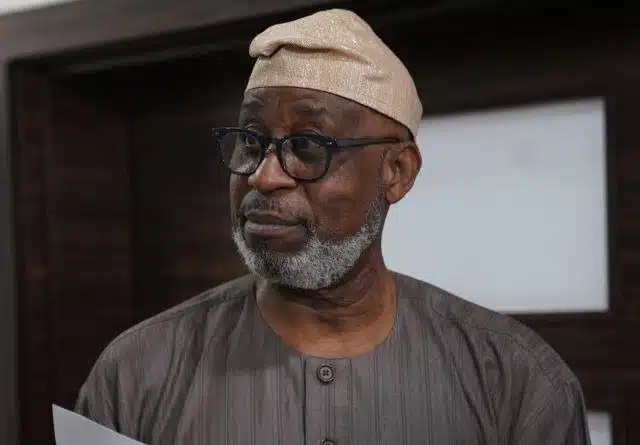

As the Minister of Works, Engineer David Nweze Umahi, is legitimately championing the use of cement for the construction of highways in Nigeria, it would be worthy were he to link up with Dr Henry Dele Alake, his counterpart in the Federal Ministry of Solid Minerals, to collaborate on processing and utilising the country’s large tar sands deposits for road construction.

Bitumen is also used in waterproofing roofs and “as a binder, in asphalt for roads, runways, parking lots, and footpaths. Gravel and crushed rock are mixed with thick bitumen, holding it together and it is then applied to roadways,” an entry on Investopedia says.

Another source says, “Bitumen and bituminous materials have been known and used in construction works since ancient times, approximately 6000 B.C. Asphalts were used as cement to hold stonework together, in boat building, and as waterproofing in pools and baths.”

Certainly, highways have been constructed with cement in many countries, including a stretch in Kogi State and the aprons of some of the airports in Nigeria.

In an article in Construction, an online publication, Sherry Sutherland, wrote, “Concrete pavements are known for their strength, durability, and longevity. In the past, they have also been associated with a high initial price. However, in a number of lifecycle cost studies, concrete pavements prevail due to their significantly lower maintenance and rehabilitation needs.”

However, asphalt derivable from tar sands and the bitumen expected from the Kaduna Petrochemical Refining Company should still be part of the mix in the construction of highways in Nigeria.

The works minister may consider encouraging highway contractors to buy all the bitumen from the Kaduna Refinery whenever it resumes refining heavy crude oil after its ongoing rehabilitation.

If the tar sand deposits in Nigeria are utilised, our country will no longer import the material from Italy, Germany, or any of the eleven top asphalt-producing countries. Astonishingly, Nigeria imports bitumen from Egypt, whereas billions of tons of its deposits in Nigeria are ignored.

This writer recollects that as governor of Lagos State, Bola Ahmed Tinubu attended one of the Mining Indabas in Cape Town, South Africa, and had a discussion on sundry issues with then Minister of Solid Minerals Development, Malam Musa Gwadabe.

Governor Tinubu’s participation in the South African Mining Indaba could be an indicator of his interest in the mining sector. That interest may now be brought to bear regarding extracting, processing, and using the tar sands deposits for the multiple benefits it holds for Nigeria as highlighted in various studies.

This is especially important as the average price of bitumen was USD1,955 per ton in 2021. This implies that if Nigeria utilises the deposits of our tar sands, the country will save foreign exchange. The high cost of building roads will also fall.

Salisu Na’inna Dambatta wrote from Abuja

Join Daily Trust WhatsApp Community For Quick Access To News and Happenings Around You.

Join Daily Trust WhatsApp Community For Quick Access To News and Happenings Around You.