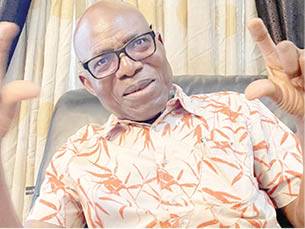

Daniel Dayo Kunle, is a highly experienced professional and renowned energy expert with over 30 years of expertise in corporate restructuring and management, acquisitions and mergers, procurement and logistic management. In this interview, he explains the flaws made by the Nigerian government that had affected the proper functioning of the Ajaokuta company and why the company needs to generate income for the government.

What can be attributed to the moribund state of the Ajaokuta Steel Company?

The problem started from the decision to site it at its current location. Which I believe made it to be structured on a faulty foundation. I am from Kogi State but the truth is that putting the company at Ajaokuta where the best iron ore is not located and there is no easy access to bring ancillary materials and minerals to support the low one, we have.

When the project was constructed, the Russians advised Nigeria to invest money in Liberia, Sierra Leone or Guinea Conakry from where we can bring high grade iron ore concentrate to make up for the deficiency in the iron ore deposit in Itakpe. If you look at the capacity of the Ajaokuta steel complex, it is 1.3 million tons per year. So, it is nothing. In fact, one Chinese family owns two of them in China.

Since we have made the error on location of the factory, the raw material that will feed it from Itakpe is already deficient and not of the high grade. So, for us to strengthen the iron ore through the process of beneficiation and transport the supporting product to Ajaokuta, you have already lost money because your total cost per ton, will hit almost $80 or $100 while a ton of iron ore concentrate in the international market, can be $50 or $60, even if the iron ore goes to $150, your own price in Nigeria at that time, will be running to $180. So, you have already lost money from just the raw material.

- Uncertainty over renewed efforts to revive Ajaokuta

- Rep petitions IGP as Benue govt seals business premises

But as an integrated steel company also, an integrated steel company means there are so many other auxiliary facilities and infrastructures that will support Ajaokuta. Those auxiliary infrastructures are not ready till today. For example, the rail line from Warri port to that place is not ready because you were to bring some items while the dredging of River Niger to Onne is yet to be done because if you were to bring limestone, with the best limestone for steel making in Nigeria in Calabar, if you were to bring it through river Niger. Also, you were to bring additional iron ore and coking coal from Lafia-Obi and Otukpo while magnesium was to be from Garkida in Adamawa or Borno for the aluminous silicate plant in Ajaokuta, the rail line from Ajaokuta after crossing River Niger towards Anyigba nobody has touched it since 1984. So, we have not built all this auxiliary infrastructure that would have supported Ajaokuta to make sense. They are all hanging uncompleted.

If you were to bring ball clay, with the in Onibode in Ogun state, that is the ball clay many people are using there now today to do ceramic, it would have to come via rail. There was a rail project that was to come from Abeokuta like that, through Osogbo to Ikare, Okene and Itakpe to bring that material to Ajaokuta; we did not do it. We did not even open up the mining site in Onibode village in Ogun state. So, if you have not done all these auxiliary infrastructures that made Ajaokuta to be called an integrated steel plant. So how are you going to run the place?

Inside that factory, you have so many other factories there, inside that complex, call it Ajaokuta steel complex, where you are going to refactor bricks, railway sleepers and many other things, their machine tools for socks, tools and mechanical tools, they are inside there like that.

Let us move to technology as in terms of technology and the trend today, you cannot use a glass furnace, a furnace that will be based on coking coal, in that place. The fuel energy required in Ajaokuta is called coking coal. The coal is very expensive because it has high calorific content and will be used to feed the blast furnace, which means you are going to produce a lot of fumes, carbon dioxide and carbon monoxide with a lot of Sulphur.

When they were building that place, it was in the jungle of Guinea savanna, the nearest town was Lokoja; the next nearest village was Adogo, the next nearest village was Okene and across river Niger was just a small trading post, Itobe, on your way to Anyigba. In that jungle that time, using coking coal for the glass furnace would have been okay but not now that Lokoja has become capital of a state and the city has grown almost into Ajaokuta itself. How are you going to be blasting furnaces and expelling so much fume into the sky? There will be acid rain two to three years down the line.

Now let us assume the federal government deliberately wants to make the place work with a deliberate policy and asks a Chinese company to take over by converting the blast furnace to gas, direct reduction technology, the one we call Arc technology. They will use gas, they will inject plenty of gas to fire the furnace, and it will reduce iron ore directly to smoothen iron plus oxygen. They will inject a lot of oxygen plus the gas, so as to save money. If you want to convert that plant today to direct reduction, you’re already talking between $500m to $1bn because you are going to dismantle the coal furnace section and convert it to direct deduction technology. The investor will ask you, why will he put his money here when the cost of production will be too high and I will not be able to sell this steel competitively. This is the tri-lemma, not dilemma, that Ajaokuta is facing.

So, what is the way forward?

The way forward is what I proposed to unbundle the complex into business units, turn the whole estate between 24 and 28,000 hectares into a free trade zone and issue a C of O to the Free Trade Zone company. The company will now be the one to look for tenants to come and do business inside that complex.

So, anybody that wants to set up industry in this zone will come to take land and be a tenant. The water treatment plant will be a standalone business; the hospital will stand alone as a business, the power plant inside, the aluminum silicate plant stand, the oxygen plant, and the mechanical tool shop will all be standalone. This will affect the four steel rolling mills too.

Then you can dismantle the glass furnace unit. The place has never been ignited, so it has never worked because they didn’t complete it. It is the only 5 percent job left for Ajaokuta to be completed.

Your analysis implies that Ajaokuta should not be used for its main purpose of producing steel. What do you think this portends for the country in terms of self-sufficiency in steel production?

For now, since our level of industrialization is very slow, we will just continue to import steel. Our basic needs for steel have been for building and construction. We will be importing while some local producers will continue to produce at a very exorbitant price for iron rod and wire as we don’t have a flat sheet plant in Nigeria. It is unfortunate, because it is another specialty.

So, we will continue to import, in addition to whatever the local operators are able to produce, but we will never be competitive. We will continue to pay a very high price for steel because there is so much capacity all over the world. They will sell to us and since we are not industrialized and the economy is not growing at five, six or 10 percent, steel requirement is very low. If our economy is highly productive and its growth is inching towards 10 percent then the volume of metal and metal needed will also go up exponentially. We will continue to import it because nobody will invest his money in this part of the world.

You will recall Dangote was planning to go into it, it is because he saw the window, and that window is still there. If you put a big steel plant by the ocean, just produce liquid steel and convert that liquid steel to flat sheet bloom and billet, People will now come and buy it to convert to many other things. That is what this country just needs. But like I have said, I don’t see how the investment will come for now.

On the issue of low-grade iron ore, what is way out of it?

We don’t have a deep pocket to buy technology that will do the mining and do the beneficiation to upgrade it because the national iron ore mining company in Itakpe, built only phase one of the beneficiation plant, which is idle today. It worked partially for some years and since then, it has been shut down. The capital investment to do mechanical mining of iron ore in Nigeria is huge and we don’t have it.

The iron ore grade we have is between 20, 30 and in some places 40%. The low level of a beneficiation plant like the one in Itakpe is crucial to steel production in the country, thus we need a modern plant. However, it is cheaper to buy iron ore concentrate from Guinea, Sierra Leone, Liberia, Mauritania, or you import from Brazil across the ocean.

Join Daily Trust WhatsApp Community For Quick Access To News and Happenings Around You.

Join Daily Trust WhatsApp Community For Quick Access To News and Happenings Around You.